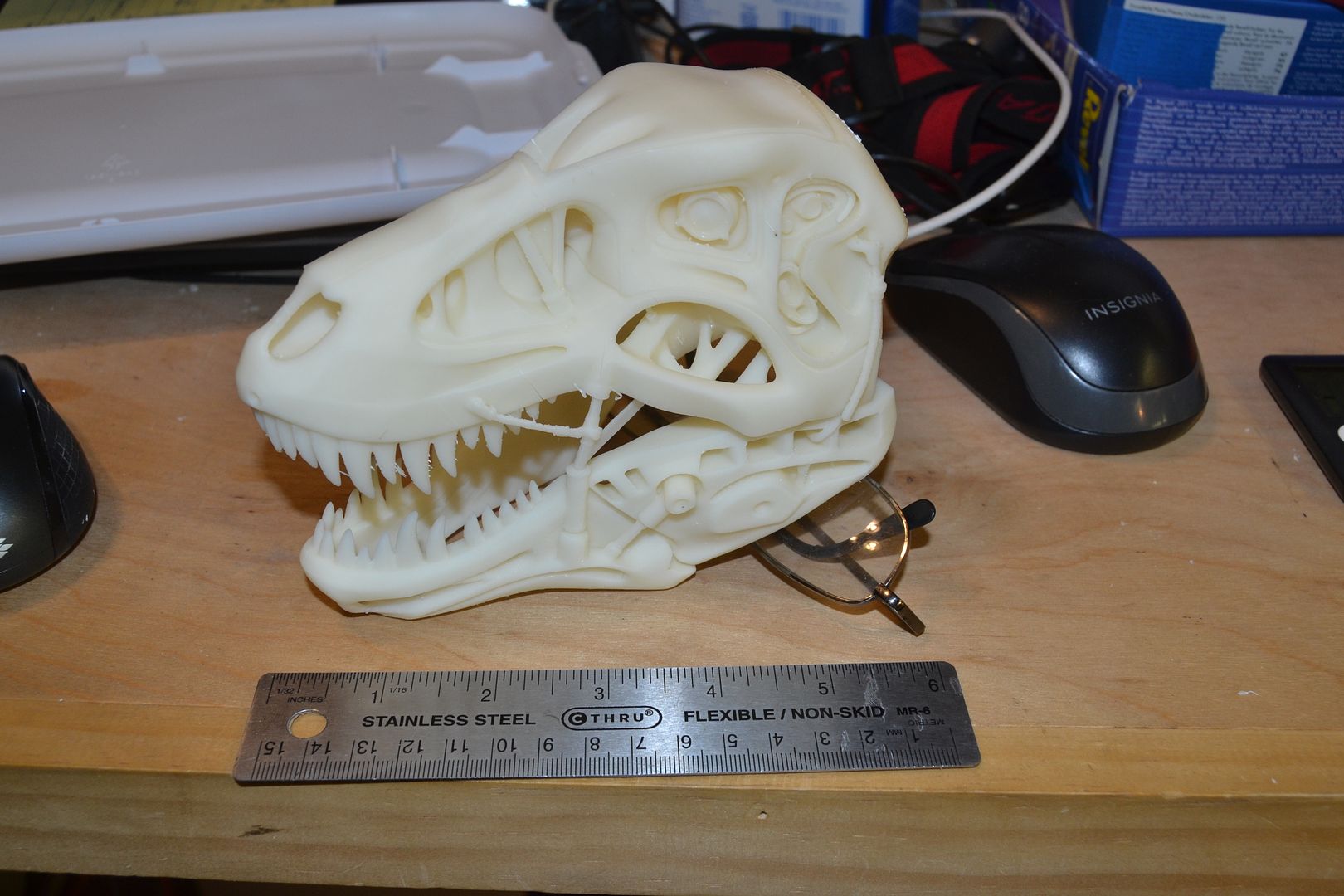

Hot off the printer (after removing the support material)

The small ruler under it is six inches long (15cm for those of you in the rest of the world)

Next a gave it a acetone vapor bath to smooth out the print layers and 2 hours later...

It hopefully will look something like this when done..